Rail cars carrying certain dangerous goods are equipped with thermal protection systems that protect the tanks from accidental fire impingement. In one case this sytem consists of a 13 mm thermal insulation blanket covered by a 3 mm steel jacket. Transport Canada wanted to know if these systems were degrading with time and they wanted a method to inspect these systems without actually touching the tanks.

Dr. Birk and his team came up with a thermographic technique that took advantage of solar heating and day night thermal cycles of tanks to see insulation defects. The system worked well and is now used by Transport Canada inspectors.

The system uses a low cost uncooled thermal imaging camera. The following images show how the procedure was developed and gives examples of tanks with obvious defects.

These two figures show the test pattern used to study the sensitivity of the inspection technique. The lab tests considered the following:

The test pattern was used with a range of temperature gradients (the gradients were added using cold water in the back of the test appartatus). The tests showed that even low cost imagers could detect defects with small temperature gradients (a few degrees C). The testing also showed that view angle to the surface was very important.

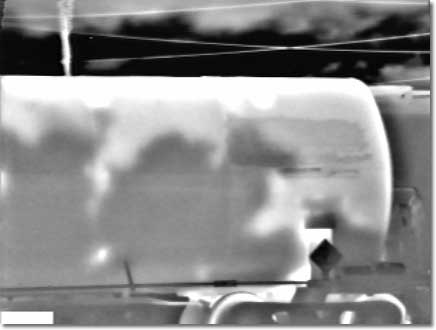

The following figures show examples of tanks with and without defects. As can be seen in the next two figures the tanks clearly have insulation defects. In both cases insulation from the tank top has dropped down to the bottom of the insulation annulus thereby exposing the tank top with reduced thermal protection.

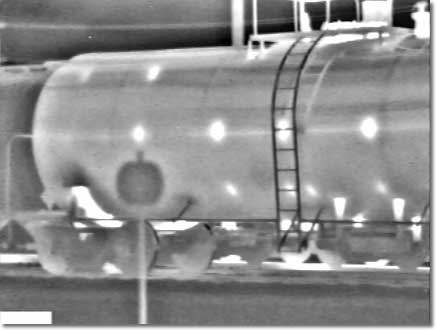

The next two pictures show tanks with good insulation. The spots you see are spacers used to hold the steel jacket off the tank wall. This is a normal condition and validates the inspection. If an inspection is carried out and there is no indication of anything, then either the tank is perfect (unlikely) or there is no temperature gradient (bad inpsection condition).

The following image shows the final camera selected for the job. It is the Texas Instruments (Raytheon) Palm IR 250. A low cost, uncooled 7-13 micron Focal Plain Array (FPA) Imager. The camera is mounted along side a video camera so that visual images can always be compared to thermal images.